MACRO Exams

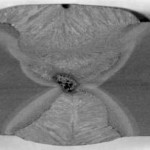

Macro Weld Examinations are performed on a polished and etched cross-section of a welded material. A number of different etching reagents may be used depending upon the type of examination to be made. Steels react differently to etching reagents because of variations in chemical composition, method of manufacturing, heat treatment and many other variables. During the examination, a number of features can be determined including weld run sequence, important for weld procedure qualifications tests. As well as this, any defects on the sample will be assessed for compliance with relevant specifications. Slag, porosity, lack of weld penetration, lack of sidewall fusion and poor weld profile are among the features observed in such examinations. It is normal to look for such defects either by standard visual examination or at magnifications of up to 50X. It is also routine to photograph the section to provide a permanent record. This is known as a photomacrograph.

Macro test is also performed on the test specimens exposed to other tests such corrosion resistance test, passivation, salt spray test, case depth measurement.

The most common test is weld cross section examination to reveal internal discontinuities, weld profile, weld passes and sequence, extent of penetration and the quality of weld.

ANS performs weld macro examination to satisfy the requirements of our clients’ needs.